Digitalization has become a new trend. Everything, from clothing to estate planning, has become easily accessible for customers. The market is ever-evolving, so digital transformation in the automotive industry has become necessary. If someone wants to gain the upper hand in the automotive industry, he/she needs to apply digital tools in manufacturing and retailing. Many companies and individuals have already streamlined their processes by accepting and applying digital transformation in their industries. In the upcoming years, we will see a substantial increase in the usage of digital technologies in automobiles.

If you are unaware or have little information and want to gain in-depth knowledge about automotive digital transformation, then you are at the right place.

Digital Transformation in the Automotive Industry

Digital transformation in the automobile sector refers to using or leveraging digital tools and technologies to increase efficiency in operations and get more customer engagement. Due to digital disruption in the automotive industry, automobile companies have started implementing digital tools in manufacturing, marketing, and automotive digital retailing. The automotive industry has slowly taken steps to allow the digital and physical worlds to go hand in hand. To boost the sales and customer experience, showrooms use software and many big companies that are well-known in the automotive industry have emphasized digital transformation in the automotive industry. Therefore, one cannot grow without being innovative. To increase efficiency, manufacturers use connected systems and data analytics.

What is Digital Transformation in Automotive Manufacturing?

Simply put, it is a way of applying digital tools and methods that can make the manufacturing process more efficient, require less labor cost, reshape the approaches, and augment the industry capabilities of traditional businesses. Automotive digital transformation allows one to streamline their production process. Robotics and automation are already in use for manufacturing in automobile companies. Digital technologies now allow one to monitor the equipment and find faults or errors before they occur. Digital transformation focuses on data-driven and AI to derive info regarding the manufacturing process and allows optimization in production planning and identifying whether quality needs improvement.

What is Digital Transformation in Automotive Retail?

People interested in car purchasing nowadays get information through different digital platforms. Automotive digital transformation has allowed car retailers to give customers an innovative and interactive experience. Digital tools in digital transformation allow retailers to give better experiences through online platforms which is why they have integrated modern technologies across vehicles and business operations. This makes finding and retaining new customers easier through digital transformation’s interactive tools.

What are the Benefits of Automotive Industrial Digital Transformation?

By now, you know that digitalization is the key to growing your business in the Automotive Industry. Automotive transformation has allowed businesses to track vehicles in real-time and reach more customers interested in buying cars. Still, at the same time, they have been able to reduce the cost of production and time in the manufacturing process. Those involved in the automotive industry have to face cutthroat competition. Therefore digital innovation in the automotive industry is the key to getting ahead in this race. By introducing digital solutions they can forecast the demand much more accurately and can optimize the required availability.

1. Revenue Growth

Having a solid E-commerce gives you a competitive advantage. If you show your car listing online, they have much more chances of potential customers contacting them. A well-optimized website can receive more positive feedback.

2. Enhanced Customer Experience

If you want to retain and keep your customers engaged, you need to provide them with a unique experience. Applying digital tools and technologies helps you generate ways to satisfy customers. Some cars now have an in-built connection system and infotainment system, giving customers a better in-car experience.

3. Expenditure reduction

Manufacturers can boost their revenue and can also reduce the cost by installing digital solutions, by studying consumer’s preference data. Industries can transform their business model with a time investment in digital tools and can save their expenditure from labor costs, by analyzing the unwanted attributes of their clients.

4. Broadening customer’s reach

Dealers should surely engage with their customers and customer satisfaction should be their priority. Whereas, they should also focus on reaching the maximum audience. By improvising correct tools, and creating engaging and required content on their website or any other internet presence, they can attract more customers which will lead to the company’s revenue.

What is the Importance of Automotive Industrial Digital Transformation?

Digital transformation automobile industry makes it much easier for companies to find ways to add new technologies in manufacturing and analyze what their competitors are doing. They can use data analytics and connected systems to increase efficiency. If you still don’t believe that automotive digital transformation is important for your business, then the following points will change your mind:

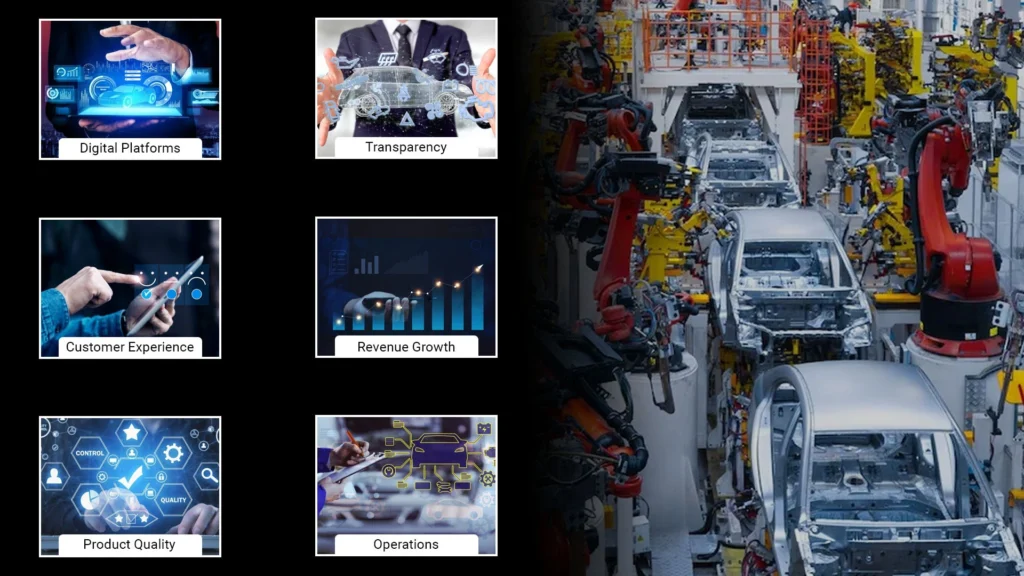

1. Presence on digital platforms

A robust online presence in the automotive industry makes it easier for retailers to reach a wider audience. Today customers are all on the internet, and what you need is the right tool and strategy.

2. Improvement in product quality

The application of digital tools makes monitoring the manufacturing process’s quality much easier. It allows data collection in real-time and informs manufacturers to identify errors and make necessary adjustments. Digital simulation and virtual data make it easier to find the manufacturing quality issue and give suggestions if required.

3. Transparency

Digital tools in the automotive industry allow more transparency between customers and dealers. Digital transformation in the automotive industry towards a generic value network has allowed customers to get every detail of the car without any physical presence.

4. Streamlining Operations

Automation and robotics enhance overall efficiency by providing real-time data monitoring and analysis, improving resource utilization and productivity.

Impact of Digital Transformation on Automotive Industry

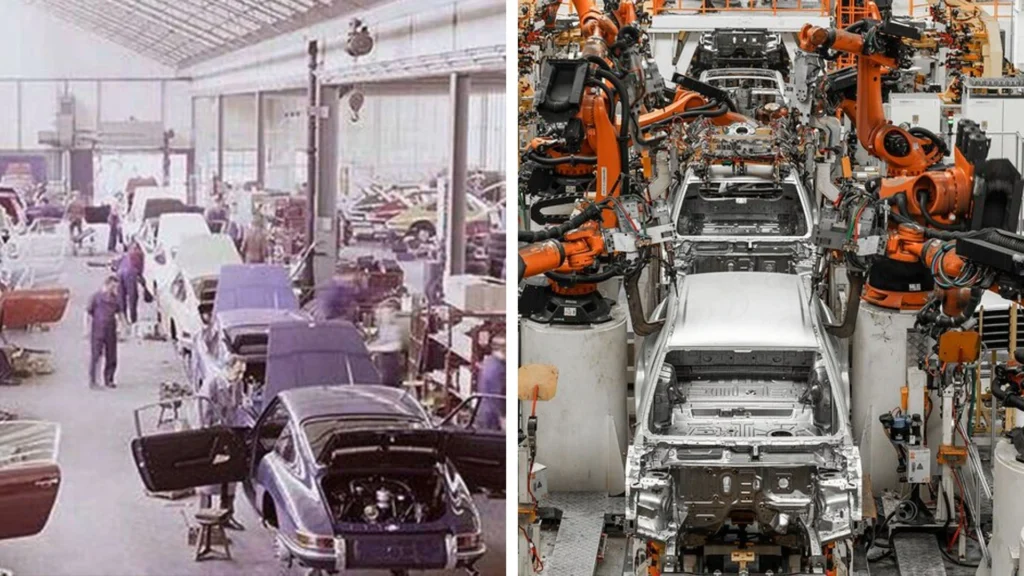

Manual and direct work was preferred more in the traditional way of automotive industry. At the time, from manufacturing to automotive digital marketing and retailing, everything required a human brain and workforce. Traditionally, manufacturing cars took longer than now since everything from the engine to designing and putting all the pieces together took a manual workforce. The decisions regarding what changes needed to be made in the manufacturing were done on the basis of what the manager was seeing in the physical presence. The cost of production was high compared to now since it took longer time and effort to manufacture automobiles on a larger scale.

All the data regarding how much input is required in manufacturing and the output numbers were all kept in a book which sometimes were lost or some wrong numbers were added due to human error. Even after manufacturing, the marketing and retailing were done through door-to-door sales, informing and finding out more customers by physically reaching out to different people. But slowly, the industry evolved, and new machines were built that automated the work during the manufacturing process. But the automotive industry entered the digital transformation later on when different software, especially, was made to understand how well the car engine was performing.

Advent of Digitization

Digital tools and visual data started playing a major role in new strategies in the modern digital era, and the traditional model was left behind. Manufacturers started evolving, and since AI and much new software started to develop, new designs and models of cars started to show in the market. Digital transformation of automotive industry allowed manufacturers to be more creative and develop more efficient designs.

After this, the retailing side of the automotive industry also adopted digital tools. Car retailers started showcasing their list online and targeting customers through dealership email marketing to reach more customers and get more engagement. To engage them, many automotive retailing websites started providing enhanced experiences like virtual car studio or 360 car photography.

What are the Top 6 Benefits of Digital Transformation in the Automotive Industry?

Implementing digital transformation can encourage automotive companies to change their business process, enhance production, increase passenger and vehicle safety, and improve the supply chain. Industries can attract new customers and lead in the market.

1. Enhance product quality

Digital tools can protect industries from losing huge losses and can help in avoiding reclamations. Manufacturers can check the quality of their products during production. Digital tools can with the help of real-time data, with help of it they can examine the defaults.

2. Minimizing the failures

Developing digital tools allows industries to monitor the failures during the manufacturing and production process. Digital technologies allow manufacturers to utilize all the resources and they can increase their productivity. While monitoring the failures, tools can also detect any faults concerning the health risk.

3. Optimizing supply chain

Tools will help manufacturers to analyze the automotive trends and identify patterns. Industries can check their inventory and can be prepared for outstocking or overstocking for error-free production. AI can help to increase digital innovation in automotive industry by examining the loopholes, and whether the materials their suppliers are providing are sustainable or not.

4. Boost customer experience

Digital tools provide you with features like an infotainment system or connective car feature. Consumers truly like these features which engage them with your brand and satisfy user’s needs. One can optimize digital tools well to provide better and futuristic features, to stand out from the market, and to provide the best experience to their customers.

5. Online existence

In this digital period, consumers are more active online rather than visiting the dealers. Industries can make their online presence with the help of digital tools and can reach a wider audience, which will spread awareness about their products and services. Digital technologies can help to gain online customer’s attention because almost 70% of the user’s shopping starts online.

6. Time and efforts

Infusing digital technologies can be a time and effort savior. You can complete the assignments in minimal time, rather than practicing and working on them manually for a long. Digital tools can complete your repetitive tasks with their software and you can utilize the saved time in creativity and strategic work. There are plenty of applications in the market that provide time management software.

What are the Digital Transformation Trends in Automotive Industry?

In the 2000s, very few people preferred purchasing a car online, but in recent years after the COVID-19 epidemic, digital trends and preferences have increased by a few technology-driven trends like electrification, autonomous driving, connectivity, and diverse mobility.

1. Increase in searches online

Auto shoppers always keep themselves updated with what is new in the automotive market. They do extensive research on various online platforms. After 2020, the searches for “Car sales” have grown globally by over 60% and are increasing yearly. Searches for “best car under” have grown by up to 80% globally. Almost 64% of auto buyers show a preference for getting information about buying cars online.

2. Preference toward online purchasing

What happens on the showroom floor plays an important role in customer satisfaction. When it comes to purchasing cars, the average time spent at the dealership is around 2 hours and 46 minutes. The longer it takes, the more the satisfaction declines. Now 63% of purchasers say they would consider ordering their car online. 73% of auto shoppers prefer negotiating a purchase, lease, or financing terms completely online.

3. Online launches

Today many car manufacturers are showing more preferences towards online launches of their cars. For example, Hyundai showcased its 2021 Elantra through a live stream. Hyundai managed to gain the interest of viewers that were watching from the comfort of their homes. The live stream and the overall walk around clip gained nearly 800,000 views.

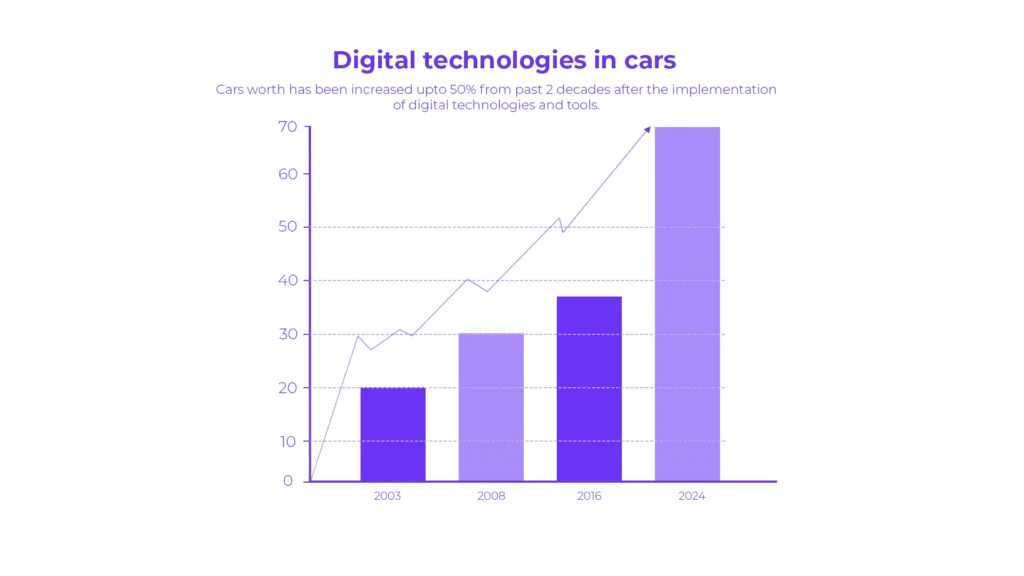

4. Digital technologies in cars

Nowadays, Technology in the automotive industry has made cars more complex and digitally advanced. Many features that are added now in cars were not even invented 20 years ago. Therefore digital technologies that are now found in cars represent 50% of the total car value.

5. Automation in manufacturing

Today, the manufacturing process and supply chain is streamlined. It has provided more efficiency and less requirement for manpower. In 1990, the manufacturing plants were just 25% automated. Now it is 75% automated. Furthermore, the defect rates have dropped to 12 per million through digitization.

6. Increased Connected Automobiles

Around 84 million connected cars are on the roads of the United States. In a few years, these numbers will increase exponentially. Thus the United States is about to become the biggest market for connected vehicles.

What are the Challenges of Digitalization in Automotive Industry?

Automotive industries need to transform their operations from business management to production. Digital transformation could be a complicated process for the automotive industry as it requires a thoughtful and unique approach to stand out in the market.

Some of the challenges in digital transformation faced by automotive industries are listed below:

1. Data security

To innovate products and services, industries collect vehicle and driver data. Industries should ensure that the data of their users are secured, to build their audience trust. The manufacturers need to drive the user’s data so they can provide the features and fulfill the requirements of their potential customers as per their preferences.

2. Product quality management

Manufacturers can not compromise the quality of their products at any cost. They surely want to provide the best products and services to the customers. Digital technologies can compromise the quality of products or services. However, industries need to ensure that the digital tools that they implement result in providing the best quality products and services. Whereas, there are a lot of digital tools that ensure the delivery of the best quality products.

3. Cost management

Industries have been using their traditional methods for decades and transforming themselves could be challenging and expensive. They should be aware of the cost the digital tools. Surely, the implementation of automotive digital transformation tools and technologies could be a bit expensive. However, manufacturers can take a lot of its advantages and boost their industry.

4. Eco-friendly environment

Our new generations, millennials and Genz are very concerned about sustainability. Industries have to enhance their technologies which should not harm the environment. The implementation of digital technologies in supplying chain, data management, and shipping processes is harming the environment.

What are the Trends of Digital Transformation in Automotive Manufacturing?

Manufacturing companies are shifting their businesses online as customer’s preferences are evolving. To reach new heights the automotive manufacturing industry also needs to develop itself. Automotive manufacturers are following their traditional methods to capture their audience’s attention, and the adaptability to evolve themselves is unsure. To reach certain desired success, manufacturers need to evolve and should shift to digital tools. Let’s look at the trends in automotive manufacturing:

1. Augmented Reality

This technology allows customers to access the assembly process of the parts being installed in the cars. They can check the quality of the parts and the location where they have been installed with their smartphones, which provides them with an error-proof assembly process.

2. Challenges in Production

After the COVID pandemic, the manufacturers have been more focused on the operation and correction of the challenges their customers are facing. Shortage of chips is one of the most challenging circumstances which is limiting the production of production.

3. OEMs revenue growth

The demand for automobiles has been increasing at a rapid growth rate, which results in profitability for OEMs. After the challenging downfall of the past few years, automotive demands are gradually increasing.

4. Increase in digital investment

Manufacturers are planning to increase up to 24% of their digital investments for automotive transformation. As the customers are evolving and their preferences are changing this is leading to creating some unknown challenges for the automotive manufacturers, because they have been using their traditional methods.

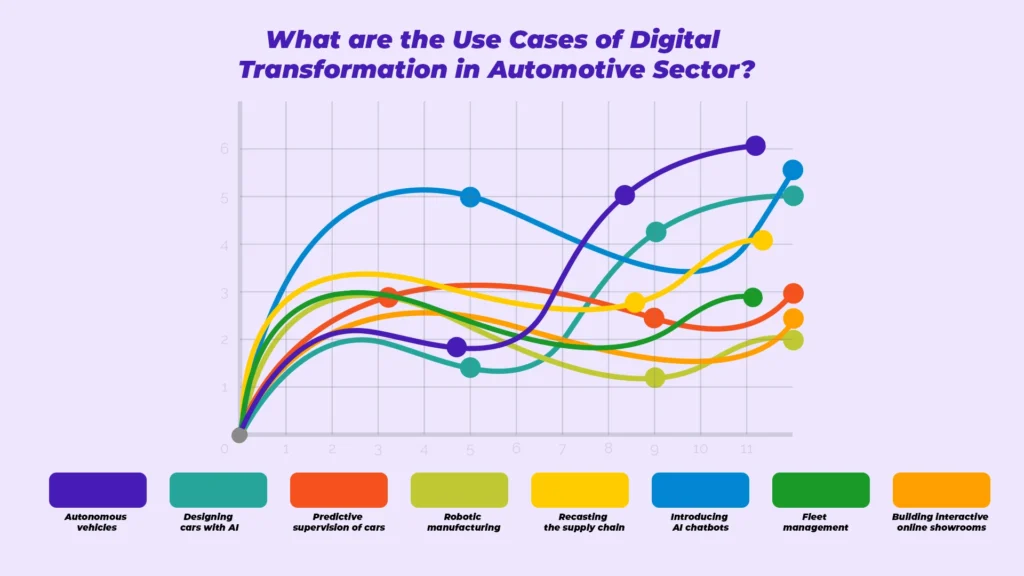

What are the Use Cases of Digital Transformation in Automotive Sector?

Most of automotive manufacturers have adopted digital tools to reach new heights. Digital transformation allows industries to give a competitive fight to the existing players in the automotive market. Let’s see how industries have applied these modern technologies to build a fortunate business.

1. Autonomous vehicles

Demand for these vehicles will increase worldwide. The prediction of autonomous vehicles in 2026 is approximately $62 billion. These vehicles are high-functioning and futuristic, which allows the drivers of the vehicle to reach their destination safely and hands-free. Surely these automated cars provide a comfortable journey for the drivers, however, they create a lot of traffic issues.

2. Designing cars with AI

Automotive manufacturers can design new models of vehicles by collecting the previous data on vehicles. Optimizing the data and using AI learning allows them to create a new car design. AI recommends manufacturers update the designs which enhances the models and reduces the cost with its powerful technologies.

3. Predictive supervision of cars

Digital technologies analyze real-time data for vehicle maintenance by following the car’s performance and analyzing the flaws in the vehicles. Supervising sports cars through digital technologies helps manufacturers prevent collisions and the vehicles are more likely to perform at their full potential in the race domain.

4. Robotic manufacturing

Installation of digital tool software to optimize the manufacturing process for automotive transformation. Integrating robotic technologies can help manufacturers identify the errors and damages in the manufacturing process which can prevent harmful and risky consequences. Digital tools can provide much more valuable and safer options in the process of manufacturing which can save the engineers valuable time in creating secure solutions.

5. Recasting the supply chain

Manufacturers can revolutionize the whole supply chain by introducing digital technologies that will allow them to decide and monitor orders. AI algorithm can predict the demand for vehicles which authorizes the manufacturers to schedule the requirements and optimize the production

6. Introducing AI chatbots

Abandon the traditional methods to interact with your clients and provide them with a new digital experience by introducing chatbots for your business. This AI tool can address the client’s queries and can promptly resolve their queries, which can save a lot of time and effort. Virtual assistants can interact with your clients support them and make your business more efficient and modern. These chatbots can understand the visitor’s requirements and provide them with the best and most easily accessible solutions.

7. Fleet management

Fleet managers can use digital tools to monitor fleet activities and can come up with decisions about route planning, asset management, and vehicle management. Automotive industries can use fleet management to run their business efficiently.

8. Building interactive online showrooms

Consumers ask for all the details online before an actual purchase. The information they are looking for is from the quality of seats to the sound of vehicles. To make your consumer’s experience better manufacturers can install digital technologies. Digital tools can make your online showrooms engaged and interactive for your consumers.

Example of Digital Transformation in Automobile Industry

Currently, we can find many examples that can showcase how much digital Transformation has changed the automotive industry, a few of which are:

1. Self-Driving Technology

AI has advanced a lot today. Many automobile companies have already implemented this technology in their cars. Automotive digital transformation has made companies use AI that is capable of driving the car itself and can help the driver reach the destination without him/her having to do anything manually. One of the big examples is cars that are manufactured by TESLA. But this technology is still going through upgrades since there have been many occasions where these automated self-driving cars have caused traffic problems.

2. Designing Using AI

Digital transformation has allowed manufacturers to use AI to design car models. Machine learning helps gather data from past models and gives newer suggestions on how manufacturers can upgrade their designs. Big automobile companies that manufacture sports cars use machine learning to design the body in a specific way so that the car can perform better.

3. Vehicle Maintenance

New components like sensor data gather information from vehicles in real time, show the car’s performance, and help identify potential problems. When they need to improve the performance of race cars, many sportscar companies use real-time data to improve overall performance.

4. Virtual Car Tour

Digital retailing automotive trends have showcased an enhanced experience through their websites. Many retailers now provide virtual car tours that allow digital inspection of each and every detail of the car from the comfort of their homes without being physically present.

Is there any Future of Digitalization in Automotive Industry?

Digital transformation is going to uplift and revolutionize the automotive industry. Implementing digital technologies in the automotive industry will cover all aspects from car production to customer service.

You can check below, how digital technology is revolutionizing auto industry:

1. Cybersecurity

Protection of the vehicles and the vehicle drivers is the priority of the automotive vehicle industry. Manufacturers require digital tools to prevent their vehicles been hacked by thefts. Manufacturers will experiment and innovate new technologies in the future to sustain in the market and provide the best-secured features and experience to their consumers.

2. Consumers digital preference

Automotive consumers are shifting their shopping preferences. Digital transformation will allow you to fulfill your client’s requirements and provide them with the digital experience in the purchase of automotive vehicles. In the future, clients might demand virtual test drives and to satisfy their needs you need to optimize your digital tools.

3. Production of vehicles

Manufacturers will require digital transformation in automotive industry for the production of vehicles. Industries will become more enhanced and robotic. To save time and effort industries will introduce new tools to produce smart vehicles at the minimum cost and in a highly advanced manner. Robots will take the place of humans to provide the maintenance of the vehicles which would be more efficient and quick.

4. Growth in connective cars

To provide a personalized experience to the users, advanced vehicles will collect real-time data on the vehicle’s performance and driver’s behavior to satisfy the passenger’s desires and utilize full the potential of vehicles.

How Does Spyne Help in Digital Transformation of the Automotive Industry

Spyne’s expertise in digital solutions for your virtual catalog can provide automotive retailers a big advantage over their competitors. The impact of digital transformation in the Automotive industry is big, and we, as a group of experts, know how important it is to engage the customers.

At Spyne, the solutions we provide with our AI can help you in the long run. Some tools that we provide that can help you in your digital transformation are:

1. Virtual Studio

With this, you won’t have to worry about studio rentals or waste time in finding studios made specifically for automobiles. Just click the photos through your phone guided by our AI system and then our AI will automatically edit the clicks and remove the background if you want. Later on, add your preferred background to give a more professional look to your car photography. You can add shadows and get rid of the number plate with a few clicks.

2. 360 Car Spin

If you want to level up your digital dealership, you have to provide the car’s details from each and every angle possible. Our digital tools, assisted with AI, can provide you with detailed 360 car photography, allowing you to showcase your automobile from every angle possible. Our AI will also help in providing transparency by detecting if the car has any damages and hot spotting them if found.

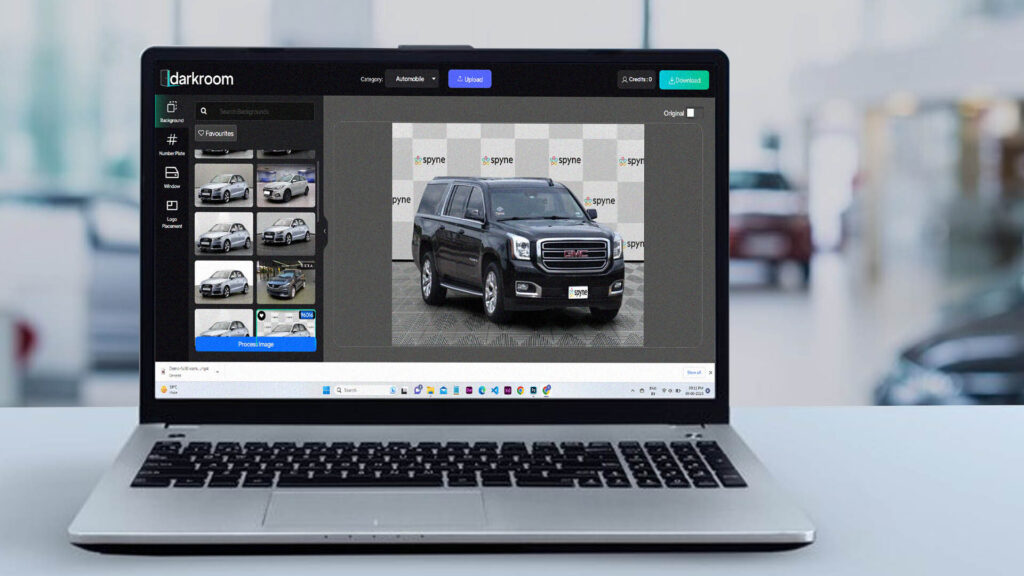

3. Darkroom

Our built-in editor is one of the best software you can find for your automobile photographs. If you want to make changes in the car or add some details to make your car photos for the catalog aesthetic, then our darkroom is the key to your doors.

Conclusion

Digital transformation in automotive industry brought positive changes in the global market of automobiles. Due to the impact of digital transformation on the automotive industry, the automation industry has become much more fast-paced. AI is providing so much data in hand that now companies can innovate and design with just the click of a button. Who knows what innovations we will see in the future?